Metes

Siemenslaan 2, B-3650 Dilsen-Stokkem, Belgium

METES – METECH is equipped with 4 Trumpf and 3 Bystronic sheet metalwork CNC Fiber and CO2 laser cutting machines. These laser cutting machines offer us unlimited flexibility in the cutting process while being the leaders in the precision �?clean-cut’ in steel, stainless steel and aluminum sheets.

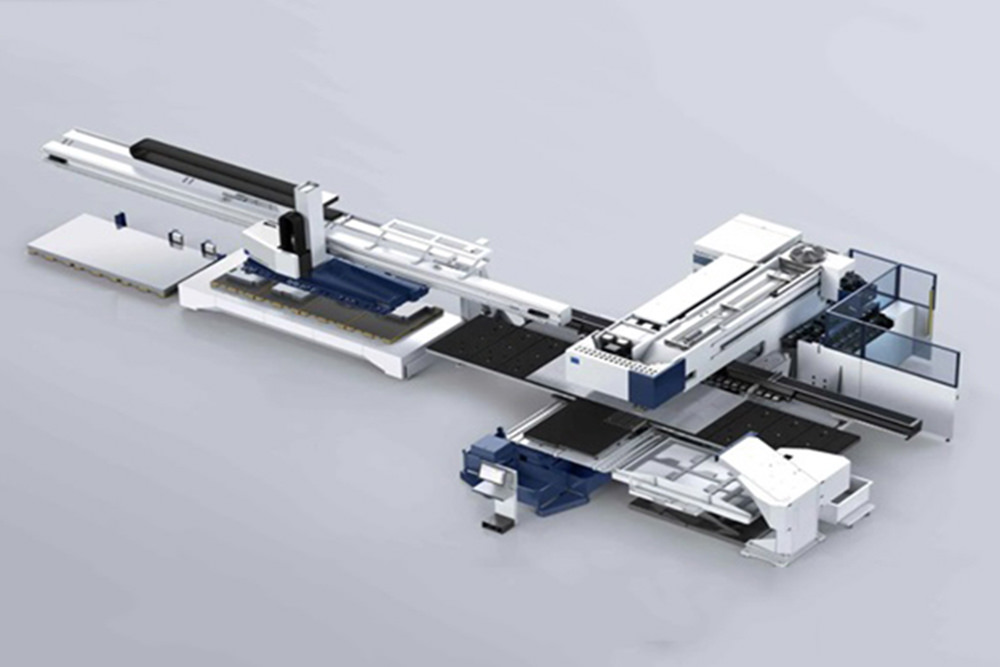

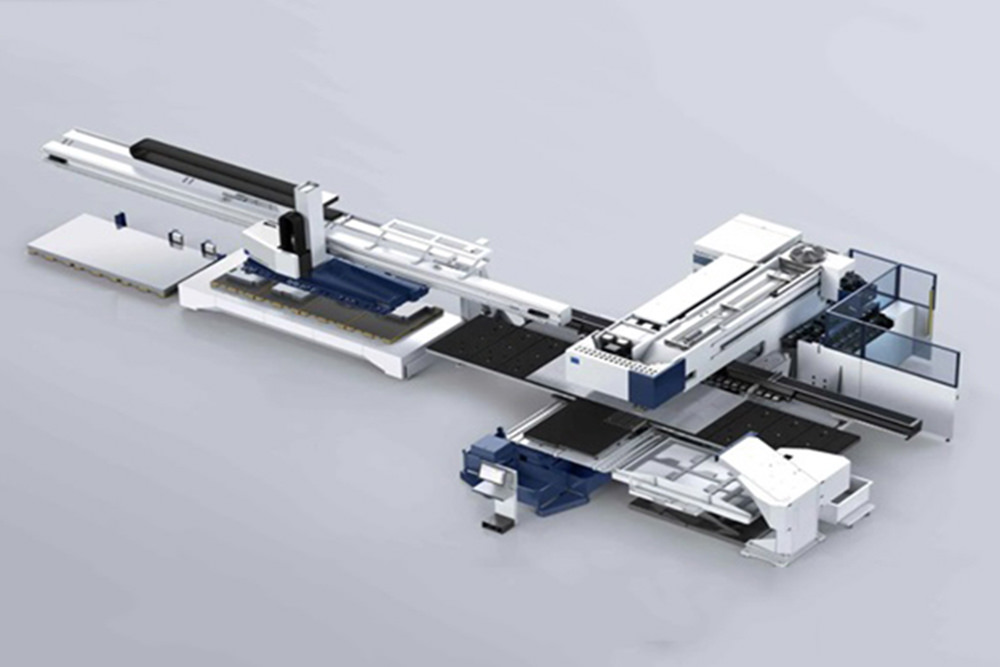

Trumpf TruMatic 7000

In 2020 we invested in the high-end Trumpf TruMatic 7000 machine including all options. With this machine we combine all the benefits of punch and laser processing. The punching head is optimal for standard countours and formings, whereas the laser cuts more complex contours. This allows us to produce a wider range of parts in a more efficient way.

Scratch free punching and laser processing is guaranteed thanks to the active die. To further guarantee a scratch free product, this machine offers automatic loading and unloading of sheets and cut parts.

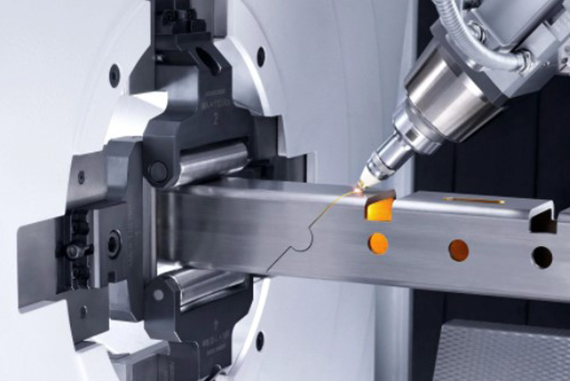

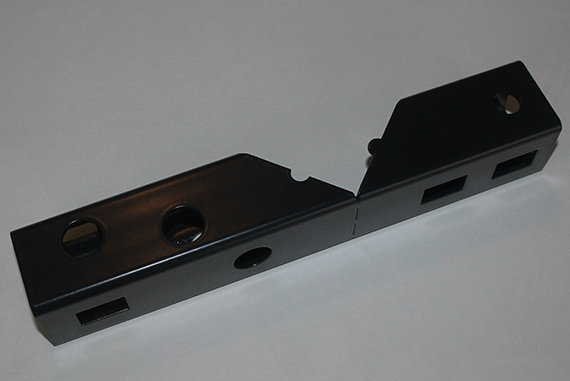

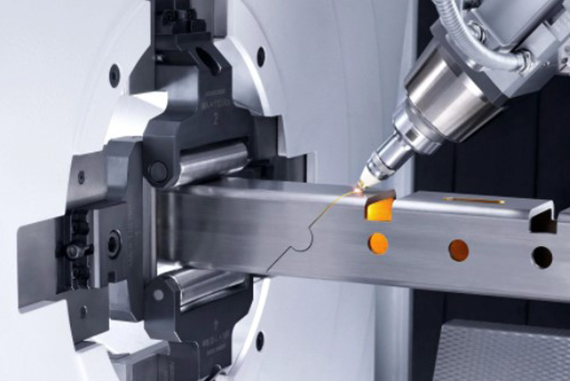

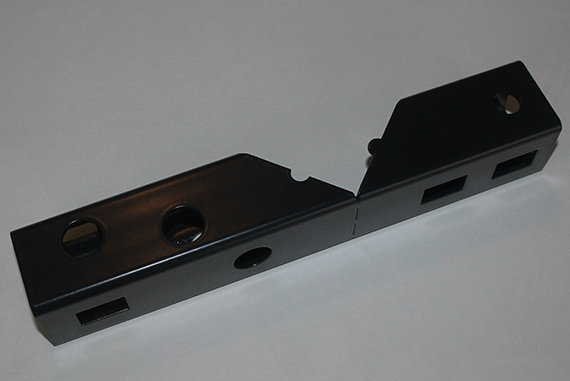

The TruLaser Tube 7000 with automatic loading unit is predestined for tube cutting. We can process tubes and profiles with diameters from 15 up to 254 mm and wall thicknesses of up to 8mm for mild steel.

The machine is steered by Trumpf Tubedesign 3D software which allows flexible and highly efficient shapes and contour cuts on tubes, U- and L-profiles. The software automatically nests parts for the most optimized material usage. Smart application of this software’s possibilities allows us to eliminate the need of bending machines, deburring and drilling. The welding process can also be simplified by preparing the parts in a smart way to reduce the need of tools, clamps and jigs for welding.

Besides sheet metal cutting and punching we also cut our own packaging and assembly materials. With the Water Jet Classica we cut materials like styrofoam, plexiglass, carton, lexan, cork, PU-foam isolation, et cetera. The maximum dimensions that can be cut on this machine are 3000x2000mm.

This machine allows us to cut the packaging materials just in time and eliminate the warehouse of pre-cut materials.

METES – METECH is equipped with 4 Trumpf and 3 Bystronic sheet metalwork CNC Fiber and CO2 laser cutting machines. These laser cutting machines offer us unlimited flexibility in the cutting process while being the leaders in the precision �?clean-cut’ in steel, stainless steel and aluminum sheets.

Trumpf TruMatic 7000

In 2020 we invested in the high-end Trumpf TruMatic 7000 machine including all options. With this machine we combine all the benefits of punch and laser processing. The punching head is optimal for standard countours and formings, whereas the laser cuts more complex contours. This allows us to produce a wider range of parts in a more efficient way.

Scratch free punching and laser processing is guaranteed thanks to the active die. To further guarantee a scratch free product, this machine offers automatic loading and unloading of sheets and cut parts.

The TruLaser Tube 7000 with automatic loading unit is predestined for tube cutting. We can process tubes and profiles with diameters from 15 up to 254 mm and wall thicknesses of up to 8mm for mild steel.

The machine is steered by Trumpf Tubedesign 3D software which allows flexible and highly efficient shapes and contour cuts on tubes, U- and L-profiles. The software automatically nests parts for the most optimized material usage. Smart application of this software’s possibilities allows us to eliminate the need of bending machines, deburring and drilling. The welding process can also be simplified by preparing the parts in a smart way to reduce the need of tools, clamps and jigs for welding.

Besides sheet metal cutting and punching we also cut our own packaging and assembly materials. With the Water Jet Classica we cut materials like styrofoam, plexiglass, carton, lexan, cork, PU-foam isolation, et cetera. The maximum dimensions that can be cut on this machine are 3000x2000mm.

This machine allows us to cut the packaging materials just in time and eliminate the warehouse of pre-cut materials.

© 2026 All Rights Reserved by METES - METECH.

Design BY AM Design.